TMMC is Toyota’s vehicle assembly operation in Ontario, Canada. At TMMC, we have three separate production lines: two in Cambridge and one just down the highway in Woodstock. Established in 1988, our 5.4 million sq. ft. facility employs over 8,500 valuable Team Members. Thanks to these Team Members and the Toyota Production System, TMMC is the most awarded plant for quality in the Americas and has produced over 9,000,000 vehicles. TMMC is an important member of its community and aims to be a leading corporate citizen by sending zero waste to landfill every year, and by supporting local nonprofit organizations.

Plants

TMMC isn’t just one plant; our operations include three different plants — North, West and South. What they all have in common is an approach to manufacturing known as the Toyota Production System or TPS, which has literally changed how automobile manufacturers around the world produce vehicles.

TMMC North

Toyota Cambridge North Plant

Located in Cambridge, Ontario, North was retooled to build the Toyota RAV4 in 2019, becoming the 2nd TMMC plant to build this vehicle. North is also were we will build the Lexus NX starting in 2021.

TMMC South

Lexus Cambridge South Plant

Also located in Cambridge, Ontario, South is where we build the Lexus RX 350 and the RX 450h, featuring Lexus Hybrid Drive. TMMC holds the distinction of being the first plant outside of Japan to manufacture a Lexus.

TMMC West

Toyota Woodstock West Plant

TMMC West builds the popular Toyota RAV4 and RAV4 hybrid crossover utility vehicles. Located in Woodstock, Ontario, it’s the newest of our three plants.

History

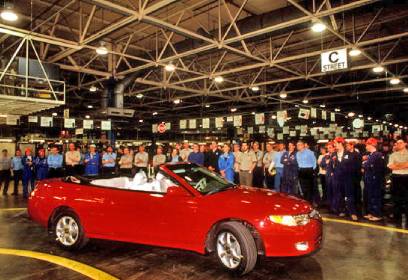

TMMC first broke ground in 1986. Since the late 80s, Canadian hands have been making Canada’s favourite vehicles. Our first vehicle rolled off the line in November 1988, and TMMC built just 153 vehicles that year. Now, TMMC has the ability to produce over half a million vehicles every year. This makes TMMC one of Toyota’s top producing global manufacturing facilities. Here is how we moved from small Canadian manufacturer to global automotive leader.

RECOGNIZED AS ONE OF CANADA’S TOP EMPLOYERS

Awards

TMMC is the most awarded automotive manufacturing facility in all of the Americas. We consistently win quality awards for our manufacturing and our vehicles, which is one of the ways we measure our success. We are proud to be one of the best manufacturing facilities in the world, currently holding 19 Plant Quality awards and 12 Vehicle Segment awards.

Plant Awards

2011, 2014, 2019

Platinum Plant Quality Award

1991, 1995, 1996, 2001, 2010, 2012, 2015, 2018

Gold Plant Quality Award

1992, 2015

Silver Plant Quality Award

1993, 2000, 2012, 2018, 2019, 2020

Bronze Plant Quality Award

Vehicle Awards

2001, 2002, 2004, 2006, 2012, 2016, 2018, 2019

Segment Award “Corolla”

2005, 2007, 2008, 2012, 2019

Segment Award “RX 350”

How We Build

Everything starts with safety – this is TMMC’s top priority, always. For the vehicles we build, TMMC prides ourselves on our build quality. It’s no surprise we’ve won 19 Plant Quality awards. All 19 awards can be attributed to our valuable Team Members and the Toyota Production System, or TPS. TPS combines Just-In-Time processing with Jidoka, automation with a human touch, to eliminate all possible waste. By eliminating all waste, every action we take adds value to the product and the customer.

Sponsorship

TMMC is a local philanthropic leader and aims to be a respected corporate citizen in the community. As part of this effort, TMMC is a proud corporate sponsor of the United Way. We also support numerous nonprofit organizations in Waterloo Region and Oxford County. The TMMC Donations Committee meets monthly to review requests for funding.

Environmental Responsibility

In 2004 TMMC set the goal of sending zero waste to landfill. Starting in 2006, we met that goal through comprehensive recycling, reusing, reducing, and composting programs. We continue to set new environmental goals every year raising the bar for our manufacturing operations.

ZERO WASTE

In almost all cases, any given person would assume manufacturing 500,000 vehicles every year creates significant waste. Think again. Back in 2004, TMMC set the goal of sending zero waste to landfill. In just two years, we achieved that goal. Through comprehensive reducing, reusing, recycling, and composting, TMMC continues to meet this goal year after year, and sets new environmental goals regularly to continue raising the bar.

WATER AND ENERGY

TMMC aims to be a good corporate citizen in its community. As part of these efforts, we developed an initiative to dramatically reduce the water used in painting cars and to use previously wasted energy to heat the water used in our manufacturing process. In total, this effort saves about the same amount of hydro that 280 households would use in a year.

ISO 14001

ISO 14001 may just seem like a bunch of letters and numbers, but it certifies TMMC’s environmental efforts. The ISO 14001 certification authenticates that TMMC has a true environmental policy and a management system designed to track its performance. Getting our ISO 14001 certification is entirely voluntary and cements our will to care for our community.

ECOPAK

ECOPAK is TMMC’s Corporate Environmental Policy. As part of our ongoing efforts to be a good corporate citizen, TMMC is committed to protecting the environment and ensuring that our automobile manufacturing processes are safe for our Team Members, the community, and the environment. Using ECOPAK, we actively promote environmental awareness among our Team Members, lead activities to protect the environment, and set environmental objectives and goals.