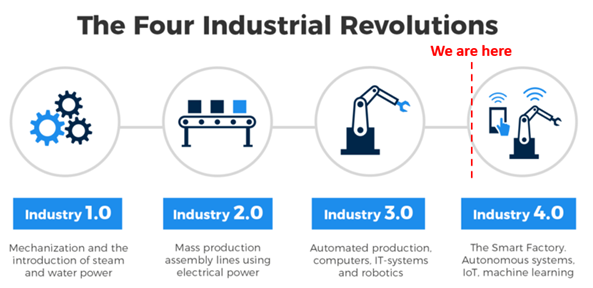

Technologies that will transform the entire automotive industry have arrived as innovations in Connectivity, Autonomy, Shared Mobility, and Electrification (CASE). At TMMC we are committed to doing things the Toyota way – by supporting our employees’ needs through technological innovation which also aligns with our progress. Technology is growing at unprecedented rates as we start the fourth industrial revolution, and the boom has rendered many tech products mere commodities.

Our focus is to find, test and put in production innovative technologies when lead to new competitive advantage; not just because they are new. If you want to innovate, then join us! You will find a company dedicated to growth where others might shy away from change.

The Innovation Laboratory

To push innovative solutions to the mainstream, we start by finding gaps in process capability. To do that, the Innovation Lab works hand in hand with the TMMC business and other companies across industries. Together, we aim to understand their root cause through collaborating with people and learning from those who see things differently than everyone else. These creative thinking techniques allow them all to find common ground on how best to devise countermeasures, all while networking constantly without losing sight of what they are working towards: solving today’s toughest problems and continuously relaying what we learn back to the TMMC community.

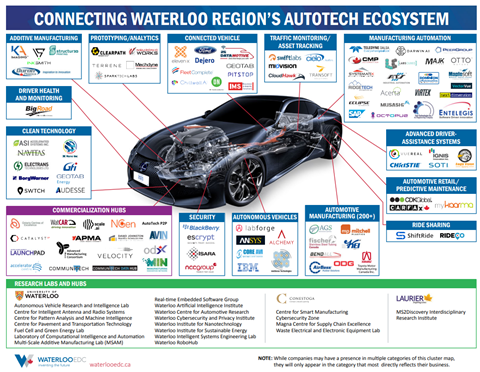

Our Network

The TMMC Innovation Team puts careful thought into developing a quality network, and it pays off every time when we take part in our Mix and Match projects. Each project poses its own technical challenge which we always find solutions for by collaborating with people from our ever-growing network – there are always opportunities for entrepreneurs to learn about how all this magic works!

Active Player as We Build the Factory of the Future

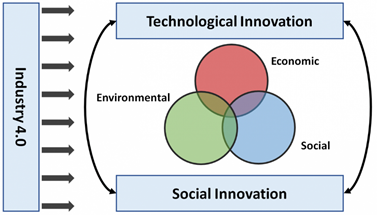

We at the Innovation Laboratory believe that contributing to the factory of the future is a cross-disciplinary endeavor. Social innovations are known as new practices used to tackle social challenges, such as the impact of Artificial Intelligence in the workforce. It isn’t just about technological innovation – there is also the matter of our cognitive understanding and social awareness too with new models, services, and products that help bring about a collective transformation in favour of a new, more healthy reality for everyone.

Embracing Technical Challenges

The Mix and Match process acts as the primary mechanism through which we communicate with senior managers, who have delegated to us high-priority items for attention. These items then become Mix and Match projects that go through the steps shown above. These often contain an innovative aspect of some kind – but all start off at Level One status, requiring review from top-level leaders before proceeding.

Finding the right partners to work with can be one of the toughest challenges for TMMC. One key aspect of this struggle is how well they learn the Toyota way and the technical jargon such as Gemba or Genchi-Genbutsu and understand the importance of collaborating with diverse stakeholders such as OEMs or Universities. This has become especially true over time due to such a highly specialized level being required.

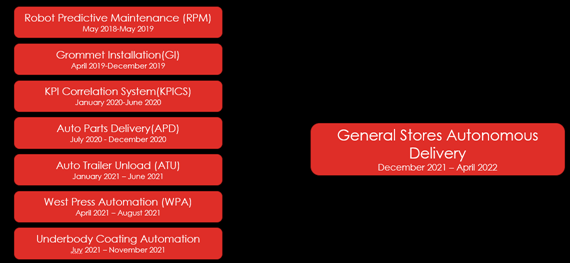

TMMC excels at taking on difficult problems. Mix and Match isn’t an exception! That’s why it was so successful. Check out our contributions since 2018 below.

Helping Transform How We Think, Plan and Work

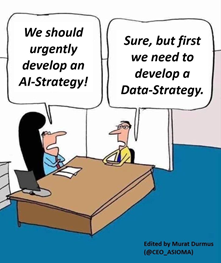

Innovation projects need the right people to adopt the right mindset, the Kaizen mindset – where they serve their customers and company and are constantly finding ways to improve. For this to happen, we all need to learn how to process information quicker and better so that we can make educated decisions when it matters most. There is innovation behind being able to analyze large amounts of data – it’s called Artificial Intelligence, and we are constantly participating with teams across TMMC to learn the tools and methods to adopt AI as part of our Industry 4.0 strategy.

This level of personal growth will become essential at every level here at TMMC as we dive into Connectivity, Autonomy, Shared Mobility, and Electrification (CASE). With robots taking care of manual labor jobs, often due to advancements in automation, we will need skillsets geared towards administration of these machines which are being integrated into society more and more.

Contributions since 2018

Production-Ready Prototypes

Toyota Internal Geo-Location Services (formerly Mesh-Net)

A foundation to connect with, maintain and help extend geo-location technology to facilitate asset tracking at any shop, plant and NAMC across TMMC and TMNA.

Visual Inspection Kit and Service (VIKS)

Low-Cost option for machine vision Deep Learning solutions based on open source and off the shelf Raspberry Pi hardware.

KPI Analytics

The goal of this project is to provide the business with a better visualization and data analysis tool with an underlying strategy.

Being Part of the Community

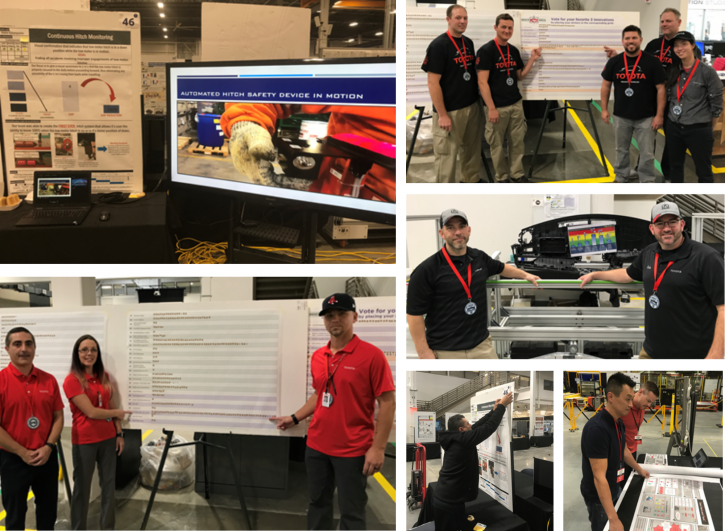

As part of our contribution to social innovation, the Laboratory hosts an annual internal event called Innovation Showcase. For the last two years, it’s been held virtually – allowing us to increase attendance from 200 to 2000.

Every year 20 and 30 innovations are showcased from all three plants. Team members vote for their top 3 picks. The top three teams present at the Production Engineering Regional Showcase at the TILT Lab at Toyota Motor Manufacturing Kentucky.

We also recognize Team Members who have been awarded a patent. Their names, as well as a replica of their patent are visible on the Patent Wall at the Cambridge Visitor Centre.

In 2019, we hosted the first Catalyst Innovation Showcase, which drew the attention of over 400 guests. Located at Home – Catalyst 137 (catalyst-137.com), we featured guided visits to the laboratory, held a conference and networking event to promote socializing with other like-minded people.

We are looking forward to hosting the next Catalyst showcase post COVID-19.